2020 / 03 / 12

How can polyethylene wax emulsion improve the abrasion resistance of ink?

Water-based inks are commonly used in cigarette, wine, food, beverage, medicine, children's toys, banknotes and other packaging and printing products with strict hygiene requirements, which require strong abrasion and scratch resistance. Among them, wax emulsion, as an essential additive, can effectively improve the role of anti-scratch, abrasion resistance, anti-adhesion, smooth feel. Polyethylene wax emulsion has stable chemical properties, smooth handfeel, high hardness, outstanding abrasion and scratch resistance, and is widely used in water-based inks.

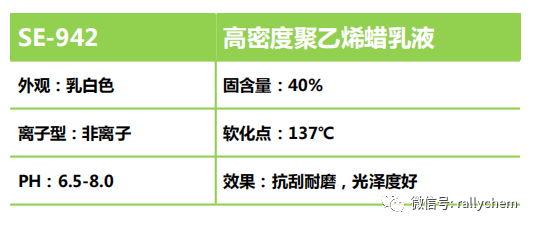

Product Recommendation

SE-942

SAMWAX SE-942 is a high melting point, fine particle size polyethylene wax emulsion developed by Rallychem Chemicals. It can effectively reduce the coefficient of friction of the ink surface and improve the smoothness, abrasion resistance and anti-scratch performance; the uniform and detailed particle size distribution can give the ink a good gloss.

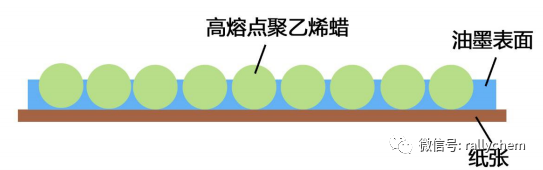

When used, SE-942 will migrate to the ink surface during the film formation process and disperse evenly to form a protective wax layer, thus achieving the effect of improving the surface properties of the ink.

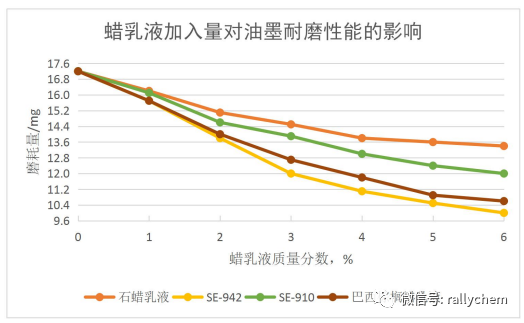

With the increase of wax emulsion dosage, the wax protective layer formed on the surface of the ink can improve the slipperiness of the paper, reduce the coefficient of friction, and the abrasion amount of the ink decreases significantly. When adding more than 5%, the space between the spherical wax particles on the surface is reduced, and then the effect of increasing the dosage is not obvious, and at the same time, taking into account the cost problem, it is appropriate to add about 5% of wax emulsion.

Rallychem Chemicals is the world's leading manufacturer of oxidized polyethylene waxes, polyester waxes and wax emulsions. We specialize in the plastics, textile, ink, and leather industries, providing trusted lubrication solutions to our customers in more than 50 countries around the world. If you have any questions about our products, please feel free to contact us!

You May Be Interested

RL - 1116S Polyester Wax: The Optimal Solution for SPC Ultra - thick Board (6mm) Internal Lubrication Challenges

2025 / 02 / 28

Comprehensive analysis of traditional PVC toughening agent: chlorinated polyethylene (CPE)

2025 / 01 / 26

Analysis of Plasticization Issues in PVC Pipes: Improving Production Quality and Efficiency

2025 / 01 / 26

Optimizing the production process of PVC conduit: improving surface smoothness and product competitiveness

2025 / 01 / 26

Why do PVC pipes have uneven inner and outer walls

2025 / 01 / 26

Whats App

For Inquiries Please Call

Rallychem Will Be Happy To Assist You!

+86 13456396233

info@rallychem.com