2022 / 07 / 21

What are the common PVC products in which oxidized polyethylene wax must be added for the lubrication of different PVC products?

We know that oxidized polyethylene wax is an extremely efficient lubricant for PVC. It is upgraded on the basis of polyethylene wax to meet the requirements of higher processing difficulty of PVC products, for plasticization and late release properties, so which products are necessary to add oxidized polyethylene wax? For example:

1. PVC transparent products, such as PVC heat shrinkable film. Because non-polar polyethylene wax and PVC are incompatible, it is impossible to produce high transparent PVC products. And the polar oxidized polyethylene wax can effectively avoid the effect on transparency and improve the release performance. But note that the amount of wax added must be appropriate.

2.PVC foam products, different from the conventional solid hard products PVC extrusion, dynamic foam molding process for PVC plasticization and melt strength have higher requirements, by adding oxidized polyethylene wax to improve the quality of plasticization and foaming, and improve the surface finish.

3. Especially thick PVC products, such as the production of ultra-thick PVC pipes, have higher requirements for plasticization, and oxidized polyethylene wax can effectively improve the production of plasticization speed.

4. Especially thin PVC products, such as PVC decorative film, require higher mold release performance in the production process. Oxidized polyethylene wax can effectively improve the late release effect.

5. Require high-speed production of PVC products, such as PVC high-speed extrusion sealing strip. For lubrication formulations better metal peeling properties are required, as well as resistance to segregation. Oxidized polyethylene wax is a very suitable late stage lubricant.

6. PVC products requiring surface finish, such as PVC injection molded fittings. The addition of oxidized polyethylene wax can significantly improve the surface gloss of the pipe fittings.

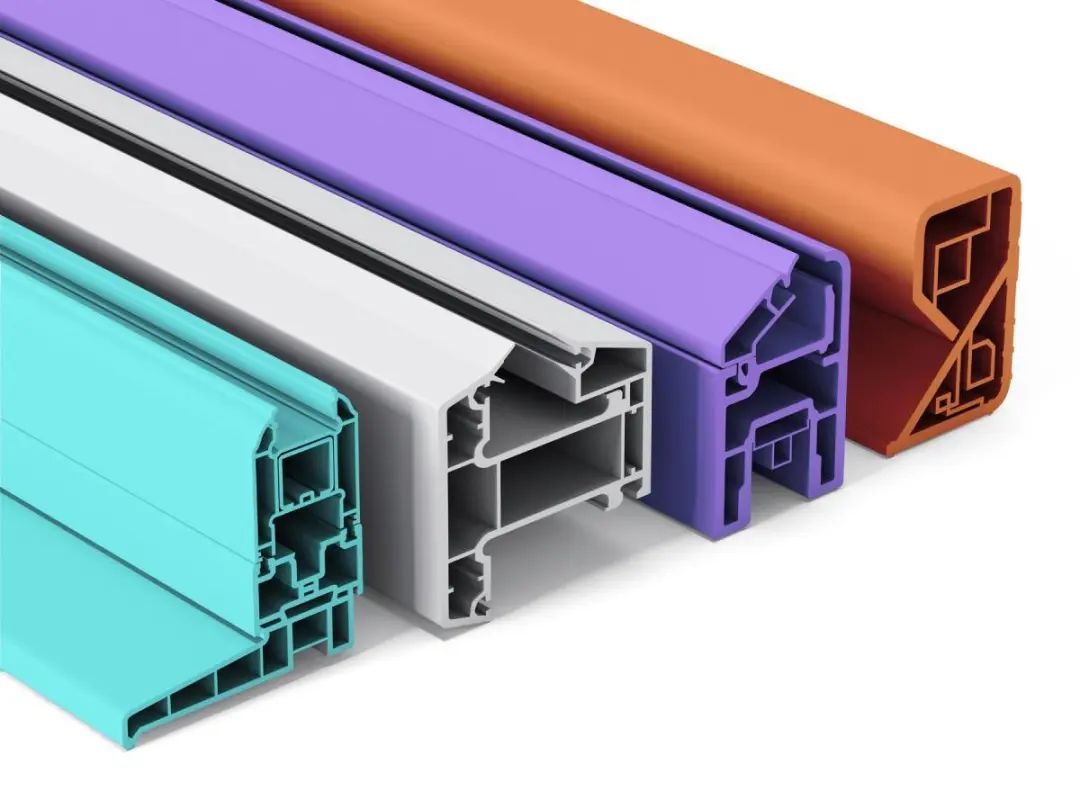

7. PVC products with complex cross-section, such as special PVC profiles. Adding oxidized wax can better control plasticization and fluidity, and avoid precipitation.

You May Be Interested

RL - 1116S Polyester Wax: The Optimal Solution for SPC Ultra - thick Board (6mm) Internal Lubrication Challenges

2025 / 02 / 28

Comprehensive analysis of traditional PVC toughening agent: chlorinated polyethylene (CPE)

2025 / 01 / 26

Analysis of Plasticization Issues in PVC Pipes: Improving Production Quality and Efficiency

2025 / 01 / 26

Optimizing the production process of PVC conduit: improving surface smoothness and product competitiveness

2025 / 01 / 26

Why do PVC pipes have uneven inner and outer walls

2025 / 01 / 26

Whats App

For Inquiries Please Call

Rallychem Will Be Happy To Assist You!

+86 13456396233

info@rallychem.com