2022 / 12 / 09

Do you know what the difference is between CPVC and PVC?

Chlorinated polyvinyl chloride (CPVC) is an important engineering thermoplastic because of its.

Relatively low cost

High glass transition temperature

High heat distortion temperature

High chemical inertness

Outstanding mechanical, dielectric, flame and smoke properties

01 What is CPVC?

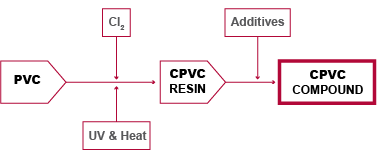

Conceptually, CPVC is a homopolymer of PVC that has undergone a chlorination reaction. Typically, chlorine and PVC react according to a basic free-radical mechanism, which can be accomplished by a variety of methods using heat and UV energy.

02 Difference between CPVC and PVC?

In PVC, a chlorine atom occupies 25% of the bonding sites on the carbon backbone, with the rest filled with hydrogen.

CPVC differs from PVC in that about 40% of the bonding sites on the backbone are filled by chlorine atoms. the chlorine atoms around the carbon skeleton of CPVC are large atoms that protect the chain from attack.

In effect, CPVC is PVC that has been subjected to further free-radical chlorination, in which elemental chlorine atoms are continually added to the polymer resin until it is 57 to 69 percent chlorine by mass. This further chlorination changes the classification of the resulting plastic material from PVC to CPVC, thereby changing the characteristic properties, operating range and acceptable application scenarios for CPVC.

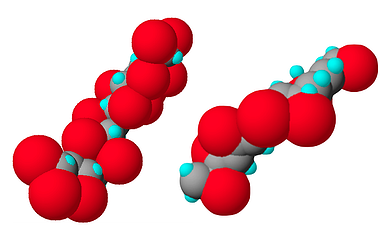

Comparison of CPVC molecules with PVC molecules

Comparison chart of CPVC (left) and PVC (right) at the molecular level. Red spheres represent elemental chlorine

✦ Enhanced temperature resistance ✦

As the chlorine content of CPVC increases, the glass transition temperature (Tg) - the temperature region where a polymer transitions from a hard, glassy material to a soft, rubbery one - increases dramatically.

It is the additional chlorine molecules that protect the polymer's carbon skeleton, which in turn protects its structural integrity from the effects of heat. This increased heat resistance allows CPVC to perform at higher operating pressures.

✦ CPVC additives ✦

CPVC resins are then infused with additives to enhance many of the inherent properties of CPVC resins while improving their processability.

It is this process that really begins to set CPVC apart from other thermoplastics and metallic piping systems and allows it to withstand the harsh environments of industrial plants.

However, CPVC tends to have extremely high melt pressures and viscosities, which means that more efficient lubricants are required to ensure stable processing of CPVC.

RALLYCHEM has extensive experience with CPVC and offers a one-stop solution.

reduces CPVC viscosity and improves CPVC processability

Improve CPVC flow, increase productivity

Avoid paste, wider processing window

Low impact on Vicat softening point

03 Basic Physical Properties of CPVC

CPVC is inherently inert to acids, bases, salts and aliphatic hydrocarbons, all of which attack the metal. It is this inherent chemical resistance, coupled with its resistance to temperature and pressure, that allows it to be used in a variety of industrial and commercial applications.

04 CPVC Product Types

CPVC is a flexible and versatile compound that can be manufactured or fabricated into a wide range of product forms or geometries using standard molding techniques, primarily extrusion and injection molding.

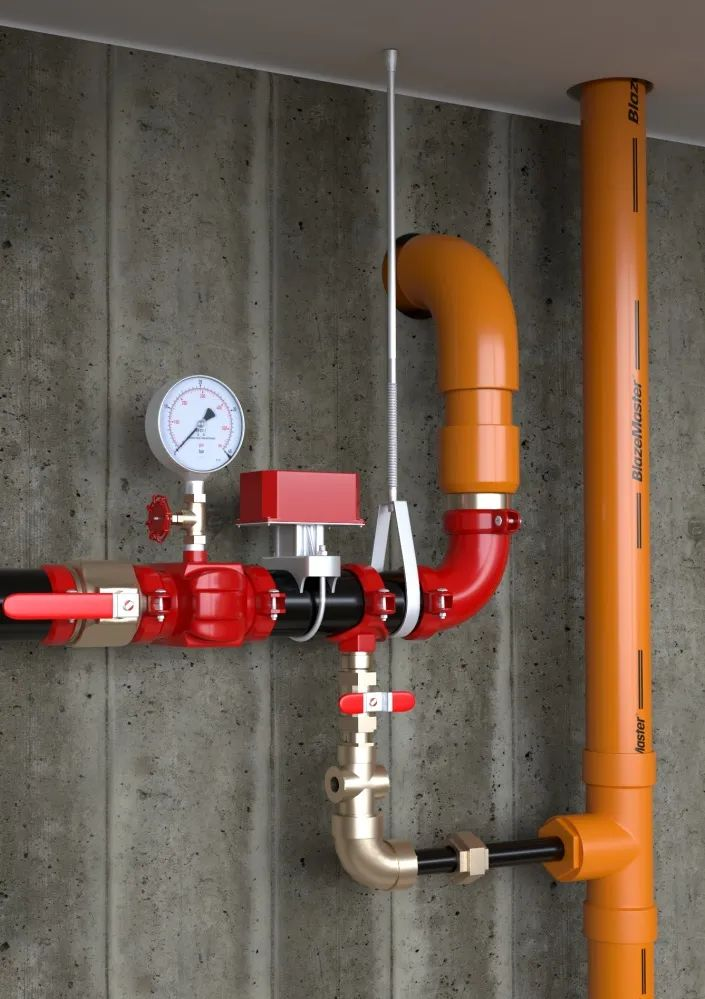

Pipes and fittings. Its corrosion and temperature resistance remains, while the pressure rating required for the application will vary depending on pipe diameter, pipe size, compound type and temperature.

Ducting. With increasing air emissions regulations, the need for reliable flue gas treatment systems is growing rapidly, especially in corrosive environments.CPVC is available in round ducts, fabricated duct fittings, industrial plates and welding rods. These components can be designed and manufactured into complete flue gas treatment systems.

sheets and liners. CPVC's excellent corrosion and fire resistance can be used in a variety of industrial applications and is wrapped in fiber-reinforced polyester (FRP).

Custom fabricated and injection molded parts. CPVC cuts cleanly and welds easily, making it ideal for products such as tower fillers, specialty exhaust hoods, and holding tanks for acids and alkalis.

✦ Common Applications for CPVC ✦

The fundamental physical properties of CPVC make it a commonly specified choice for applications ranging from chemical processing plants and mineral processing plants to residential and hospitality plumbing.CPVC is a problem-free, long-lasting solution for the harshest industrial environments and is frequently specified for the following industries:.

Chemical Processing. Reliable transportation of corrosive chemicals at high temperatures and pressures without corrosion problems.

Chlorine-Alkali. Transporting chemicals in some of the most corrosive environments imaginable without corrosion problems.

Commercial Plumbing. Eliminate corrosion, reduce maintenance costs and improve overall reliability.

Mineral Processing. Withstand the demands of precious and raw material processing operations.

Power Generation. Withstand long-term exposure to high pressure and corrosive chemicals commonly used in power plants.

Semiconductors. Meet high purity standards for cleanrooms and eliminate concerns caused by aggressive chemicals.

Wastewater Treatment. Eliminates corrosion even when transporting the most aggressive sterilization chemicals.

✦ CPVC Installation ✦

CPVC installation connection methods will depend on the product type, but in general, CPVC offers the following installation advantages.

Lightweight. CPVC weighs about 1/8 the weight of similarly sized steel, which helps reduce worker strain and injury and eliminates the need for heavy equipment.

Easy to cut. Composite properties make CPVC easier to cut than metal, allowing for more efficient on-site fabrication.

Simple to install and maintain.CPVC installation does not require complicated tools, electricity or highly skilled (and expensive) labor.

Safer. No open flames or sources of ignition are required to join the material.

There are a variety of seam welding options designed to effectively seal components together while maintaining the structural integrity of the material. Recommended installation methods will vary by product type:.

Pipe and Fittings. Solvent bonded, hot air welded, hot plate welded, threaded and flanged.

Ducts. Solvent bonded, hot air welded, thermoformed, extrusion welded and hot plate welded.

Plates and linings. High speed hot air welding and hot plate butt welding.

You May Be Interested

RL - 1116S Polyester Wax: The Optimal Solution for SPC Ultra - thick Board (6mm) Internal Lubrication Challenges

2025 / 02 / 28

Comprehensive analysis of traditional PVC toughening agent: chlorinated polyethylene (CPE)

2025 / 01 / 26

Analysis of Plasticization Issues in PVC Pipes: Improving Production Quality and Efficiency

2025 / 01 / 26

Optimizing the production process of PVC conduit: improving surface smoothness and product competitiveness

2025 / 01 / 26

Why do PVC pipes have uneven inner and outer walls

2025 / 01 / 26

Whats App

For Inquiries Please Call

Rallychem Will Be Happy To Assist You!

+86 13456396233

info@rallychem.com