2022 / 12 / 16

How much do you know about meltblown PP material?

There are many varieties of PP meltblown materials on the market, and many meltblown fabrics are prone to poor filtration efficiency, fluttering phenomenon, which will also lead to problems such as filters and molds are easy to clog, etc. The reason for this is that the process has a great deal to do with the process, but the quality of the meltblown material is also very important to the stability of the meltblown material. Therefore, to improve the meltblown fabric production and quality, in addition to mastering the PP degradation process, rigorous and meticulous control of the production process, the correct selection of meltblown material, there is a key role of twice the result with half the effort.

Application of PP meltblown material

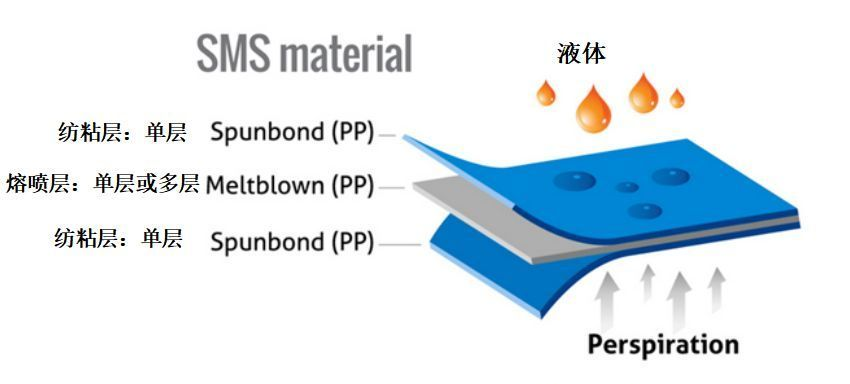

PP meltblown materials are mainly used in medical and health care, clean materials, thermal and acoustic insulation cotton, oil-absorbing materials, battery separators, air filtration, and household products, and the most important protective masks, whether N95 or disposable masks, the main structure includes inside and outside of the spunbonded layer (S-layer) and intermediate layers of meltblown layer (M-layer), the heart of the mask, the main role of the barrier and adsorb particulate matter and droplets. The main material of M layer is meltblown grade PP with high melt index (1500), whose characteristics include high melt index, low molecular weight, high stability, low odor, and formation of high-strength fiber network structure. Its main grades are distinguished by melt index, and the materials used for masks are mostly 1500 brand, with an average molecular weight of 50,000-80,000, and physical properties are almost the same as those of polypropylene plastic granules, with performance indexes including melt index, molecular weight distribution, yellow index, anti-aging time, etc.

PP meltblown material due to fluctuations in parameters, common problems in production are:

1、the melt index is not stable, resulting in uneven spinning, easy to filter efficiency is not up to standard, fluttering phenomenon.

2、ash, too many impurities, resulting in filters, molds are easy to plug.

3、High peroxide residue, odor and yellowing; secondary decomposition makes meltblown cloth hard and brittle.

How to distinguish and select high quality meltblown material

MFI:

The increase of melt index MFI can reduce the working temperature of screw extruder, which is helpful to reduce the formation of excessive degradation of polymer, prolong the life of meltblown die and reduce energy consumption. Generally choose the meltblown material with MFI 1500±100g/min, the flow rate is very high, the melt viscosity is lower, so that the meltblown fibers will be finer, and the meltblown fabric filtration is naturally better.

Ash control:

The hole diameter of the spinneret die is small, if the ash content of the meltblown material is too large, too many impurities, it is easy to cause clogging of the spinneret hole. Choosing a low ash content meltblown material can effectively extend the replacement cycle of the meltblown die, reduce energy consumption and lower production costs.

Choose high quality meltblown material:

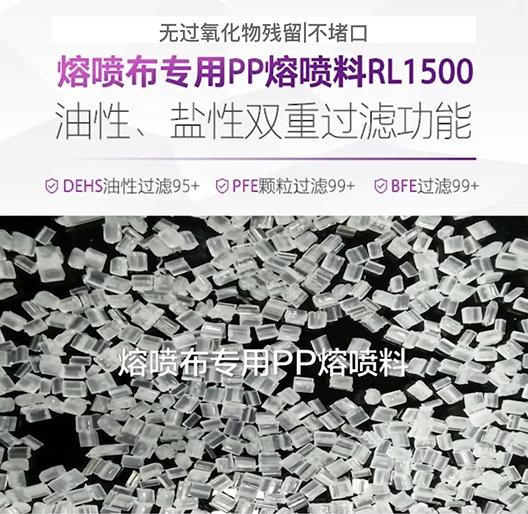

RL 1500 is a special PP meltblown material with high filtration efficiency, adhering to Rallychem's strict and professional attitude. RL 1500 is non-clogging and has no peroxide residue. Together with standard equipment parameters and electret process, we have helped many manufacturers to stabilize the production of meltblown fabrics of grade 95 and above.

Rallychem RL 1500 passed the SGS test and meets the national GB/T 30923-2014 standard. It maintains the original toughness and temperature resistance on improving the flowability of the melt, and improves the spinning fineness at higher wind pressure without fluttering.

Rallychem RL 1500 has no peroxide residue, lower odor and higher added value of meltblown fabrics.

Rallychem RL 1500 is ROHS certified, making it more environmentally friendly and healthier. It is free of heavy metals and brominated flame retardants, making it safe and secure.

You May Be Interested

RL - 1116S Polyester Wax: The Optimal Solution for SPC Ultra - thick Board (6mm) Internal Lubrication Challenges

2025 / 02 / 28

Comprehensive analysis of traditional PVC toughening agent: chlorinated polyethylene (CPE)

2025 / 01 / 26

Analysis of Plasticization Issues in PVC Pipes: Improving Production Quality and Efficiency

2025 / 01 / 26

Optimizing the production process of PVC conduit: improving surface smoothness and product competitiveness

2025 / 01 / 26

Why do PVC pipes have uneven inner and outer walls

2025 / 01 / 26

Whats App

For Inquiries Please Call

Rallychem Will Be Happy To Assist You!

+86 13456396233

info@rallychem.com