2023 / 01 / 13

Difference between spunbond, meltblown and SMS nonwoven fabrics

Medical masks consist of three layers of nonwoven fabric. The middle layer is meltblown nonwoven fabric. The top and back layers are spunbond nonwoven fabrics. They have different functions in resisting viruses. What is the difference between spunbond nonwoven and meltblown nonwoven?

1. What is spunbond nonwoven?

Spunbond nonwoven fabrics are made by continuous spinning of fibers. Polymers are extruded and stretched to form filaments. These filaments are laid down in a web. The web itself is then bonded during thermal, chemical or mechanical treatment. Through reinforcement, the web becomes a nonwoven. Applications for spunbond nonwovens include nonwoven bags, liners, healthcare workwear, masks and filters. They are becoming increasingly popular in the health and medical industries.

Raw materials used to produce anti-adhesive nonwovens include PP (polypropylene), Pet (polyester), nylon and PE (polyethylene). The most commonly used is PP, which offers stability, heat resistance, aging resistance and breathability.

2. What is meltblown nonwoven fabric?

The process of meltblown is to convert polymer fragments into a web-like fabric. Commonly used raw materials are PP and PE. After extrusion, filtration and pumping, hot air blows the fibers from the meltblown die to form a finer, tangled web. This simplicity of processing gives it a significant cost advantage over other systems.

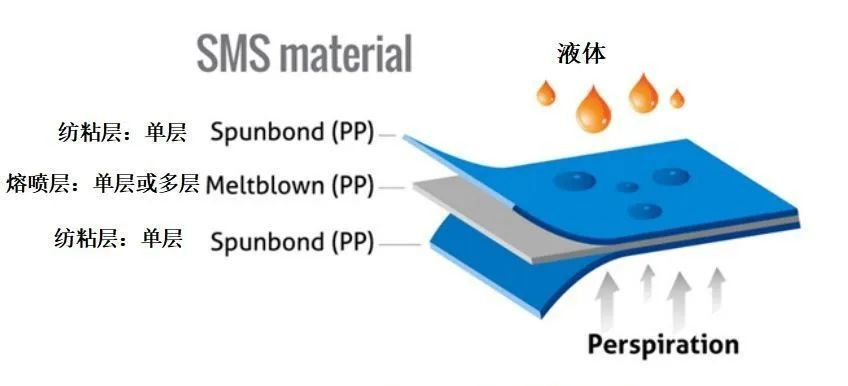

3. What is SMS nonwoven fabric?

SMS nonwoven is a three-layer structure consisting of spunbond, meltblown and spunbond. It has the same structure as a sandwich. The top layer is spunbond nonwoven. The middle layer is meltblown. Then the bottom layer is spunbond again.

4. Differences between spunbond, meltblown and SMS nonwoven fabrics

Difference in production process

The production process of spunbond nonwoven fabrics is simple. All procedures are done on the nonwoven production line. The steps are as follows:

The raw material PP is loaded into the silo with the necessary additives.

The extruder dissolves and extrudes the material.

A filter removes impurities from the PP solution.

The rotating system starts working. It rotates and stretches the PP solution into long, thin fibers.

The filaments are formed into a web. The web is then produced into a nonwoven fabric by their own methods (bonding, thermal bonding, chemical bonding or mechanical reinforcement).

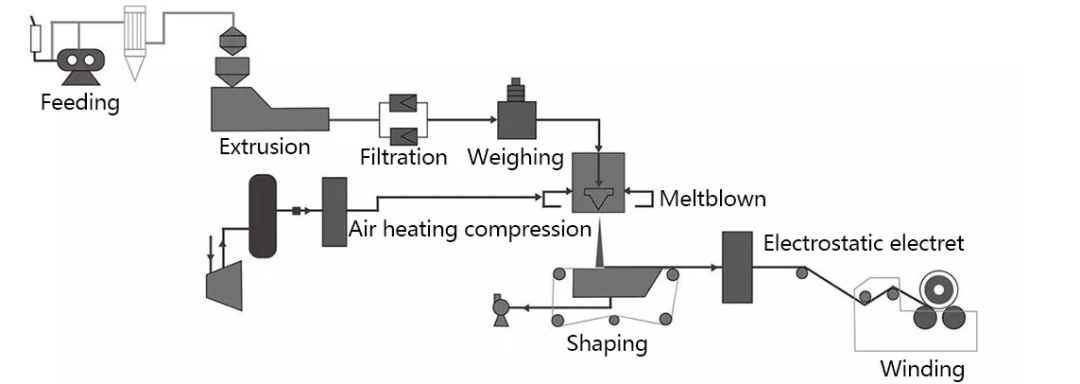

The manufacturing process for meltblown is shorter than for spunbond:

The raw material PP does steps one through three automatically.

The PP is extruded into a melt.

The melt is filtered and metered by a pump and flows into the spinning box.

In the spinning box, a spinning die ejects the fibers. Hot, high-pressure air blows the fibers into thin, long fibers.

Meltblown nonwoven fabrics are formed and hot rolled out in rolls.

SMS nonwovens are produced in both the spunbond and meltblown methods. The spunbond and meltblown methods work independently in front of a rolling mill. They are then integrated into a three-layer fiber, the SMS nonwoven.

Characteristics

Spunbond nonwovens are moisture resistant, breathable, flexible, lightweight and non-combustible. They are also non-toxic, non-irritating, environmentally friendly and recyclable. They are also colorful and inexpensive.

Meltblown nonwoven fabric is lightweight, three-fifths of cotton. It is soft and comfortable to the touch. Meltblown fabric is waterproof, breathable and non-absorbent. Meltblown fabric has good filtration properties, which is required for medical masks.

SMS nonwoven fabrics have a great advantage in water repellency. Spunbond nonwovens are characterized by their durability and strength in wet or dry conditions, resistance to abrasion and breakage, and hardly absorb any moisture. The inner layer of meltblown fabric gives a soft touch and is water repellent.

5. Applications

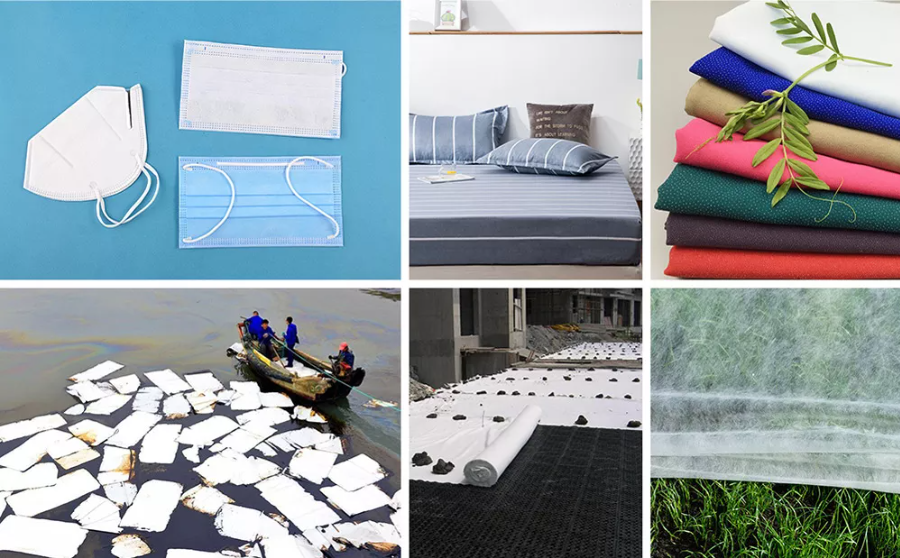

Applications of Spunbond Nonwoven Fabrics

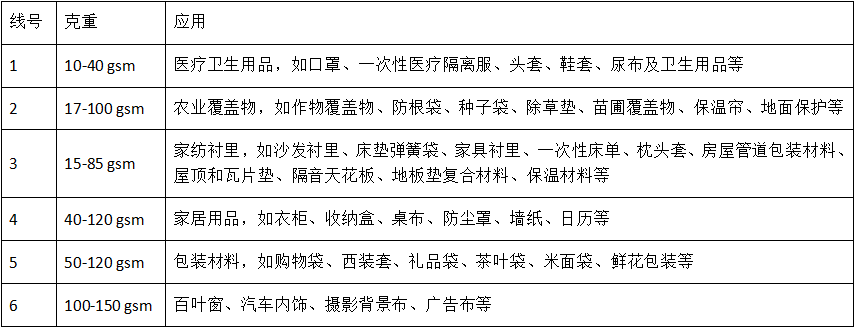

Spunbond nonwoven fabrics are mainly used in medical materials, agricultural coverings, home textiles, packaging materials, shopping bags and so on. It usually depends on the grammage of the nonwoven.

Applications of Meltblown Nonwoven Fabrics

Meltblown nonwoven fabric is the core material for masks and filtration materials. It is a good material for liquid filtration, insulation, absorption, thermal insulation, oil absorption and wiping.

Application of SMS Nonwoven Fabric

There is a huge market for SMS nonwovens. The end product usually varies depending on its thickness.

Thin SMMS products perform well in terms of waterproofing and breathability. They are particularly suitable for the hygiene market, such as sanitary napkins, sanitary pads and baby diapers.

Medium thickness SMS products are suitable for use in medical products. They contain surgical gowns, surgical drapes, surgical cloths and sterilized bandages. After being treated with alcohol, blood and oil repellent and anti-static, this nonwoven fabric becomes ideal for high-quality medical protective equipment. These cloths can also be used for workwear and protective clothing.

Thick SMS products are widely used as highly efficient filtration materials for various gases and liquids. They are also highly efficient oil-absorbing materials. They are used in industrial waste water degreasing, offshore oil cleaning and industrial wipes.

You May Be Interested

RL - 1116S Polyester Wax: The Optimal Solution for SPC Ultra - thick Board (6mm) Internal Lubrication Challenges

2025 / 02 / 28

Comprehensive analysis of traditional PVC toughening agent: chlorinated polyethylene (CPE)

2025 / 01 / 26

Analysis of Plasticization Issues in PVC Pipes: Improving Production Quality and Efficiency

2025 / 01 / 26

Optimizing the production process of PVC conduit: improving surface smoothness and product competitiveness

2025 / 01 / 26

Why do PVC pipes have uneven inner and outer walls

2025 / 01 / 26

Whats App

For Inquiries Please Call

Rallychem Will Be Happy To Assist You!

+86 13456396233

info@rallychem.com