2022 / 07 / 28

Oxidized polyethylene wax and PE wax, where are they in the actual processing of PVC?

Knowing is not only important, it is also important to know why. Understanding the microscopic location of PE waxes and oxidized polyethylene waxes helps us to understand the lubrication principle more intuitively and scientifically, so that we can optimize our formulations to produce better PVC products.

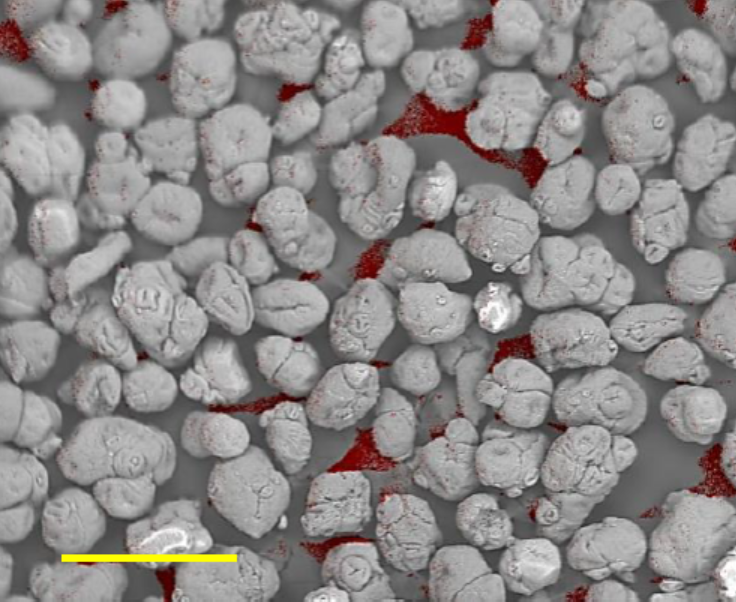

According to a study by the University of South Africa, by using a scanning electron microscope, it is possible to observe the microscopic behavior of PE wax in the actual processing of PVC. We can see that the gray is PVC particles and the red is polyethylene wax. The non-polar polyethylene wax cannot combine with the PVC particles due to its incompatibility with PVC. It mainly acts between the particles of PVC. It plays the role of external lubrication that delays plasticization and avoids PVC resin sticking to metal screws and barrels.

Fischer-Tropsch wax behaves similarly to PE wax in that it acts as an external lubricant.

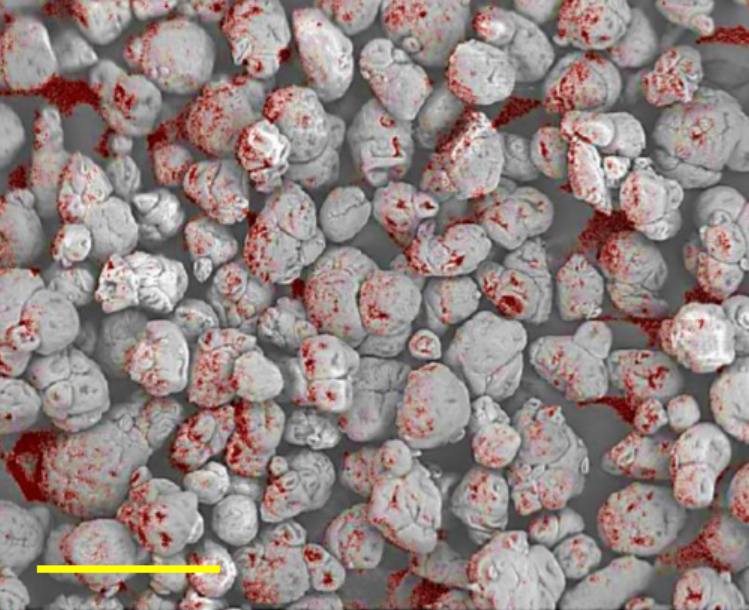

The oxidized polyethylene wax, on the other hand, carries a polarity that enables it to combine with the PVC resin. Through the scanning electron microscope, we can find that compared with PE wax, oxidized wax is able to coat each PVC particle better, which is equivalent to putting on a lubricating coat for each PVC particle precisely. Therefore, during processing, no matter how the screw is sheared, there is no loss of lubricating properties and the release of mold is guaranteed at the late stage of processing; the internal lubrication of oxidized polyethylene waxes also promotes plasticization, which improves the processing efficiency and increases the daily production volume of the factory; and in the case of PVC products filled with high-calcium powder, the

In the case of high calcium filled PVC products, the oxidized polyethylene wax provides better protection for the screw, thus prolonging the screw's service life.

You May Be Interested

Breaking 3 Technical Barriers! How Rallychem Redefines Premium PVC Transparent Shrink Film Solutions

2025 / 04 / 23

RL-1116S Polyester Wax: Solve SPC Ultra-Thick Board (6mm) Lubrication Challenges

2025 / 02 / 28

Comprehensive analysis of traditional PVC toughening agent: chlorinated polyethylene (CPE)

2025 / 01 / 26

Analysis of Plasticization Issues in PVC Pipes: Improving Production Quality and Efficiency

2025 / 01 / 26

Optimizing the production process of PVC conduit: improving surface smoothness and product competitiveness

2025 / 01 / 26

Whats App

For Inquiries Please Call

Rallychem Will Be Happy To Assist You!

+86 13456396233

info@rallychem.com