2022 / 08 / 01

What does the acid value of oxidized polyethylene wax represent in PVC processing?

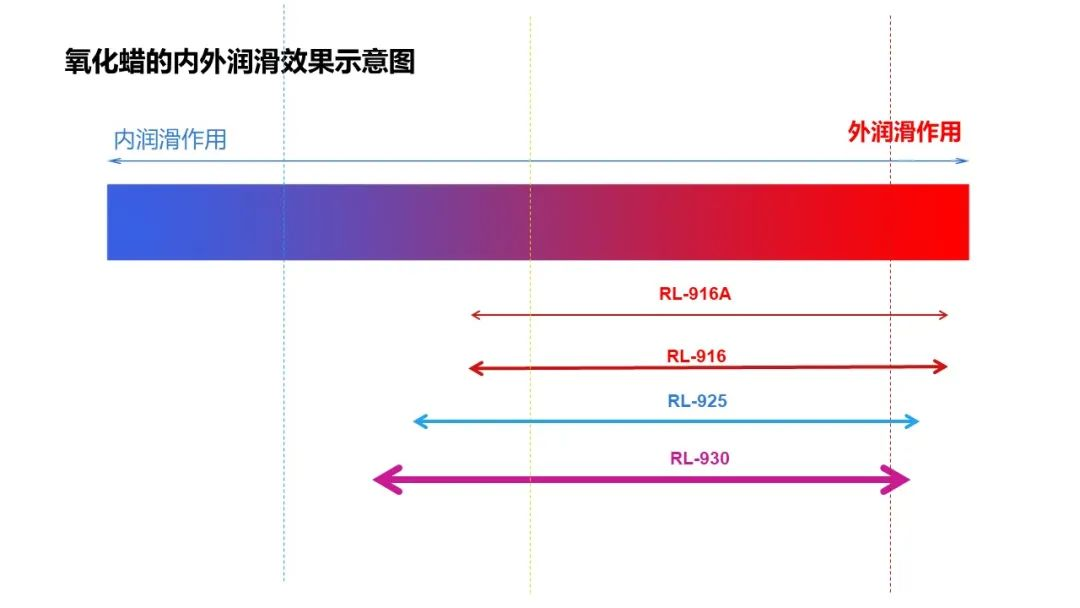

Oxidized polyethylene waxes are used as both internal and external PVC lubricants. There are a number of common models on the market, such as 916, 925 and 930, which represent acid value 16, acid value 25 and acid value 30, respectively.

Generally speaking, the acid value represents the polarity of the oxidized wax and is positively correlated. The higher the acid value, the higher the polarity of the oxidized wax. In practical PVC processing, a higher acid value means that the oxidized wax has a more pronounced internal lubrication effect and increases the speed of plasticization. For example, the plasticizing speed of 930 with acid value 30 is significantly faster than that of 916 with acid value 16, so it is more suitable for PVC products with higher plasticizing requirements, such as SPC flooring, stone wall panels and other highly filled products.

On the other hand, when the acid value of oxidized polyethylene wax is higher, it is more in favor of internal lubrication, and its external lubrication effect will be relatively weakened. Therefore, oxidized polyethylene waxes with low acid values are more suitable for PVC products with high demands on post-molding and surface. For example, shrink films, calendered sheets, etc.

Therefore, 916A with an acid value of 16 can be used as a good late release agent after plasticization has reached the required level.

You May Be Interested

RL - 1116S Polyester Wax: The Optimal Solution for SPC Ultra - thick Board (6mm) Internal Lubrication Challenges

2025 / 02 / 28

Comprehensive analysis of traditional PVC toughening agent: chlorinated polyethylene (CPE)

2025 / 01 / 26

Analysis of Plasticization Issues in PVC Pipes: Improving Production Quality and Efficiency

2025 / 01 / 26

Optimizing the production process of PVC conduit: improving surface smoothness and product competitiveness

2025 / 01 / 26

Why do PVC pipes have uneven inner and outer walls

2025 / 01 / 26

Whats App

For Inquiries Please Call

Rallychem Will Be Happy To Assist You!

+86 13456396233

info@rallychem.com